Compressor / Main PCB Blink Codes

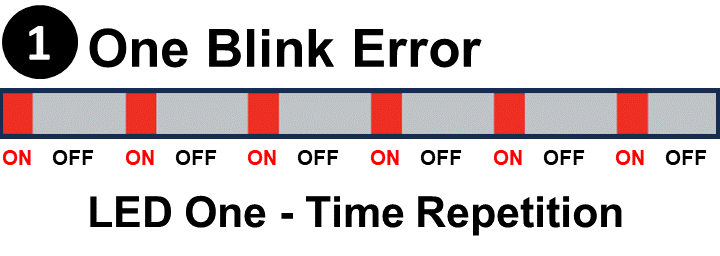

Cause: Main PCB Compressor voltage errors.

What to check: Check compressor voltage from in PCB and if not good then replace Main PCB.

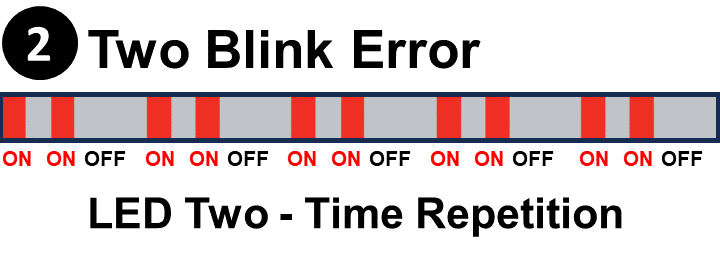

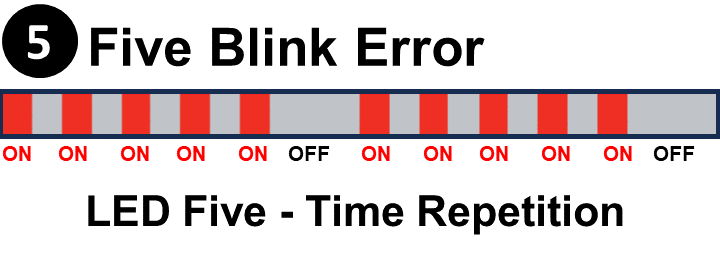

Cause: PCB Parts defect or Compressor connection (Piston over run)

What to Check: Check compressor wire harness for tight connection. If connection is good then replace Main PCB

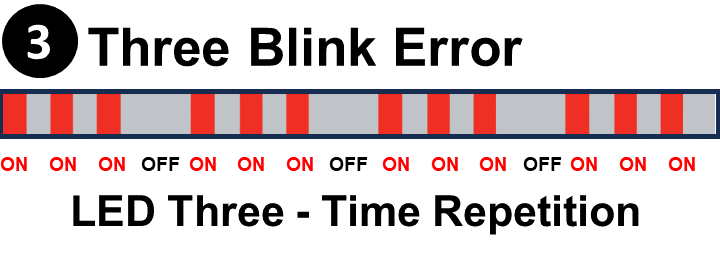

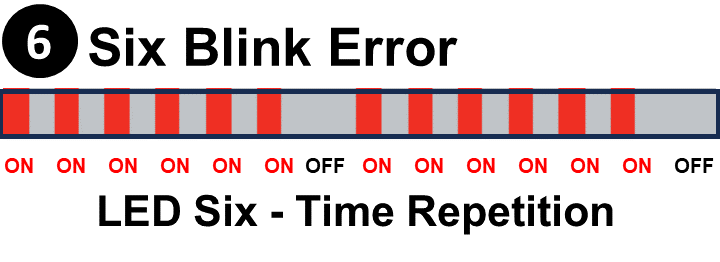

Cause: Open circuit, Wire harness connection failure between Main PCB, Compressor, Capacitor

What to Check: Check for loose wire harness / connections. Check compressor winding for possible open reading (the most common issue)

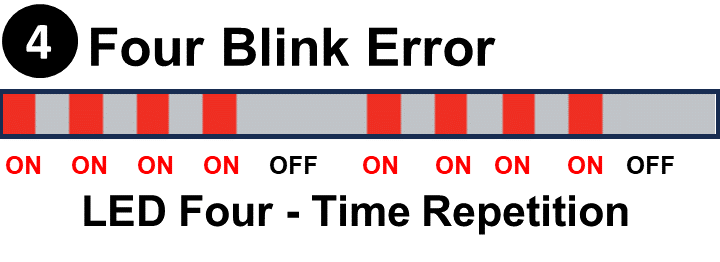

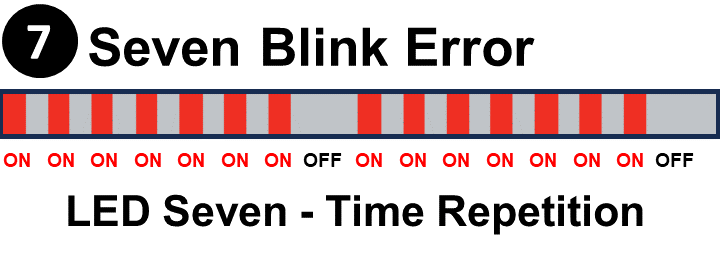

Cause: Outlet clogging

What to Check: Restart unit, if blink code returns check the Main PCB for proper voltage, if voltage is incorrect replace the Main PCB, If the voltage is correct and the blink code persist replace compressor.

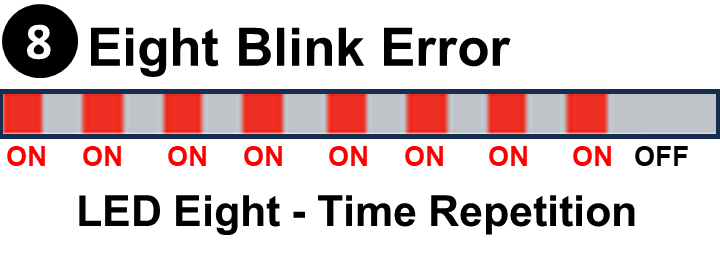

Cause: Piston constraint, Compressor defect.

What to Check: After resetting power, check if the compressor is running. If still does not run, then replace the compressor.

Cause: Current Trip, high compressor amperage, most often caused by low side leak.

What to Check: Check the sealed system condition especially for a low side leak. Moisture pulled into the sealed system causes the compressor to get very hot due to moisture and non-condensables mixed with refrigerant. Expect the pressures to be higher than normal on the high side.

Cause: (IPM Fault Trip) PCB Parts defect, Main PCB.

What to Check: After resetting power, check if compressor is running, If the Compressor still does not run replace the Main PCB.

Cause: (Board Protection) Board Protection from shorted DC component.

What to Check: DC component failing, isolate failed component…Examples of defective parts we have seen produce this blink code have been flow meters, fans, sub board etc…

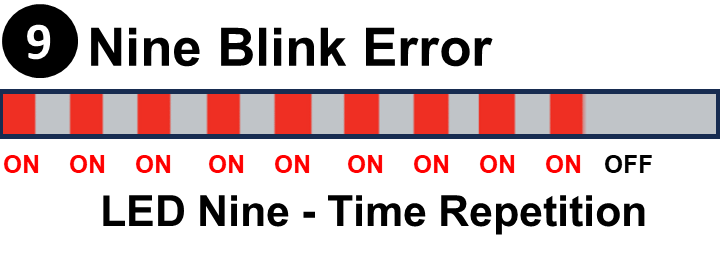

Cause: (Power Trip) Overload Protection

What to Check: Put in test mode, if the 9 blinks repeats check if the Main PCB outputs less than 60V if it does replace the Main PCB. If the output voltage is 60V or greater, the issue will be sealed system related.

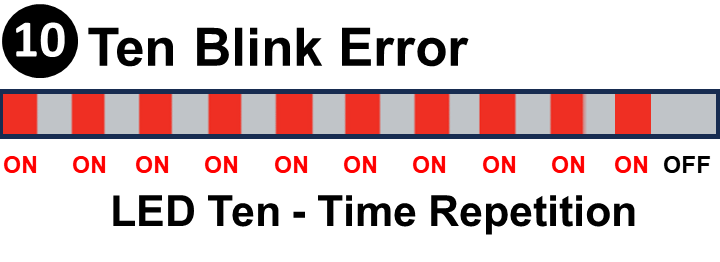

Cause: (Overload Trip) Compressor Overload Protection. Abnormal high temperature detected in machine room (Over 43°C / 109.4°F)

*Note: There is not a thermistor located in the machine room area. This blink code is determined by load on the compressor circuit on the Main PCB.

What to Check: Condenser fan, dirty condenser, installation clearances, or other things that can affect airflow. If not cooling correctly and everything is clean, fan is operating, and airflow issues have been ruled out, it could be a low side leak, compressor issue, or other sealed system issue causing excessive load on the compressor.

If the unit is cooling correctly but producing this code and everything above is ruled out then Main PCB could be defective.

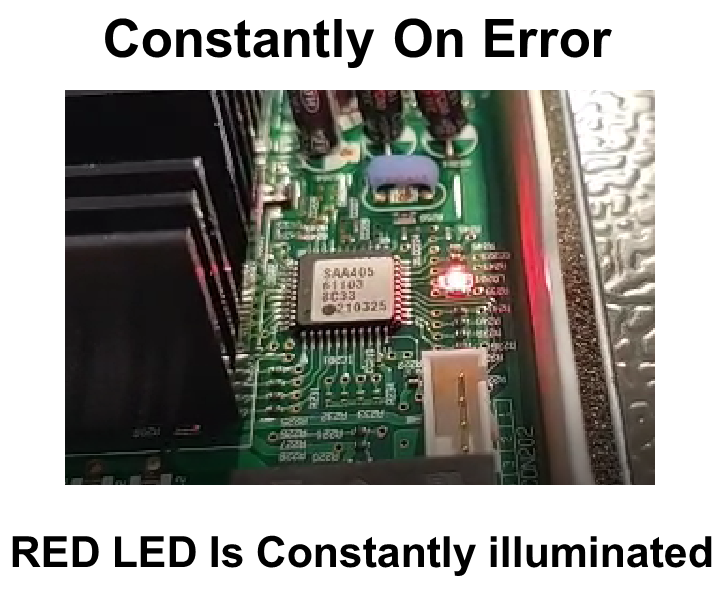

Cause: PCB, Parts defect Main PCB

What to Check: After resetting power, check if the compressor is running. If the compressor still does not run replace the Main PCB.