INSPECTING FOR CONTAMINATION

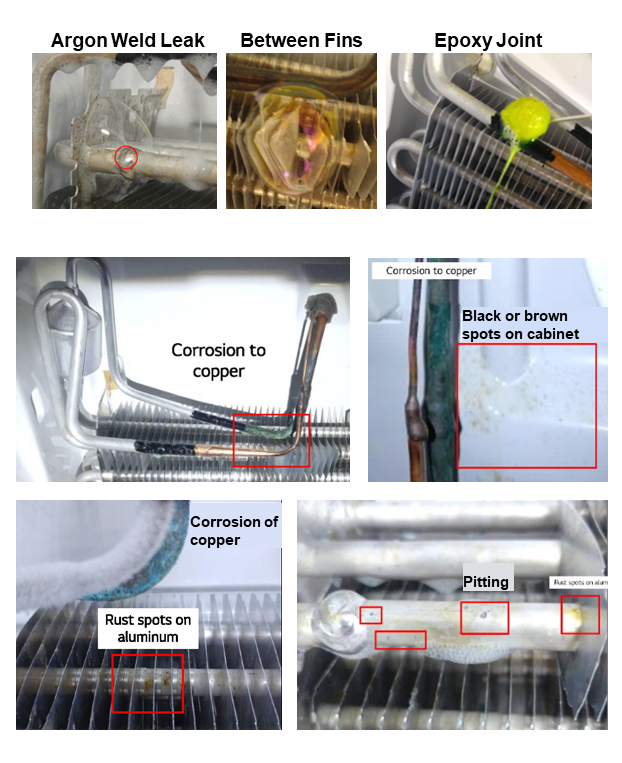

Be sure to inspect components for contamination. Below are some examples of the sludge/powder that is often found inside the sealed system:

Many times the above examples of contamination are caused by low side leaks. The low side is the suction side and will pull moisture into the system. When moisture mixes with the oil in the system it creates sludge that causes restrictions within the sealed system. Here are some examples found with nitrogen pressure testing.

If you see evidence of contamination pressure test the system with nitrogen and use your bubble solution to identify the leak (typically a low side leak). The electronic leak detectors, and dye / glasses, are a great additional tool to help find a leak, but nitrogen pressure with bubble solution will be the best way to detect the leak.

The contaminants will typically “settle” in certain areas more than others.

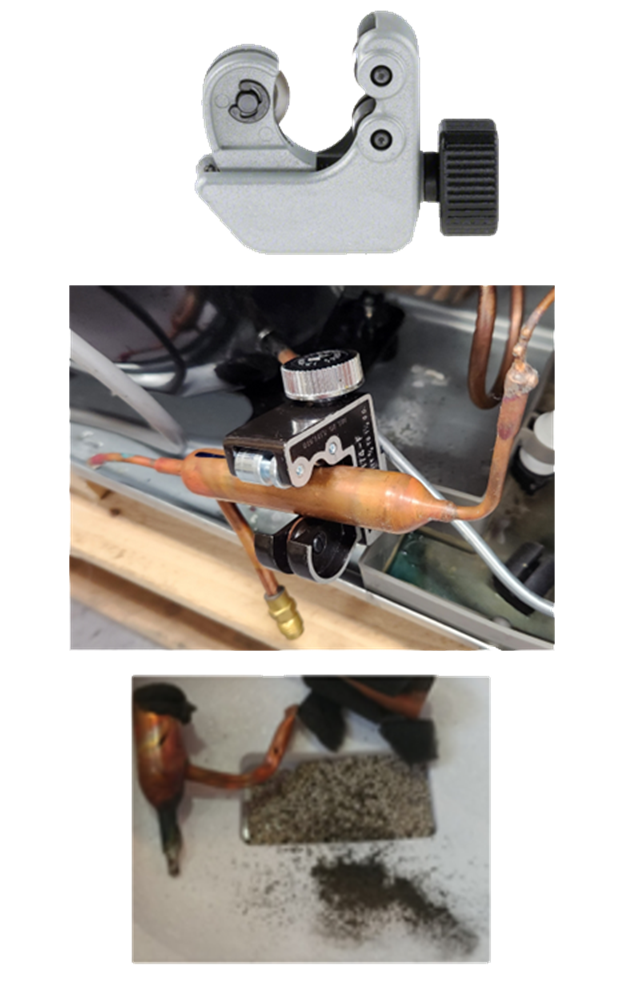

* The Filter Drier. The drier is designed to filter the sealed system as it operates, as it does so it will collect debris, so cutting a drier open can indicate the condition of the sealed system.

* The Condenser. If there is evidence of contamination in the condenser, simply replace it, it will be easier and more efficient than trying to flush it.

* The High Side Loop. It is always advised to flush the high side (Yoder loop) as containments will settle there also.

* Capillary Tube(s). If you find contamination in the drier it would be best to flush out the capillary tube(s) to make sure you have a clean path to the evaporator coil(s).

* Evaporators. If you find contamination inside the evaporator coil(s), it is often better to replace the coil than try and flush them out.

Use the tubing cutters to open the drier and inspect it.

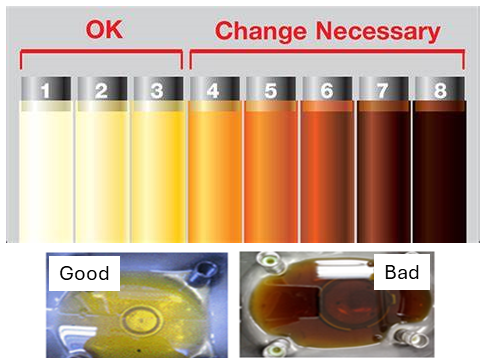

Also, Check the color of the compressor oil. The compressor oil should be a light color. If it appears dark this is an indication of moisture/contamination in the system and you know that thorough flushing will need to take place.

Use a white paper towel or transparent cup and drop several drops of compressor oil to check the color. Refer to the below color guide. If the color of your compressors oil matches example 4-8 then replacing the evaporator, compressor, and drier will be needed along with thorough liquid flushing.