FLUSHING INTERNAL TUBING PROCEDURE

Flushing the System

When you open the Sealed System to repair any defect, it is always recommended to flush the system. Most of the time a leak will cause a sealed system issue and introduce non-condensables into the system but even an inefficient compressor could cause some contaminates in the system that must be removed to ensure proper operation and no reclaims.

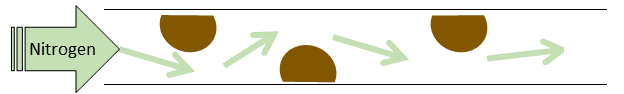

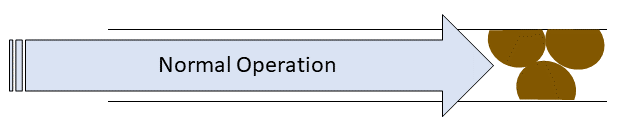

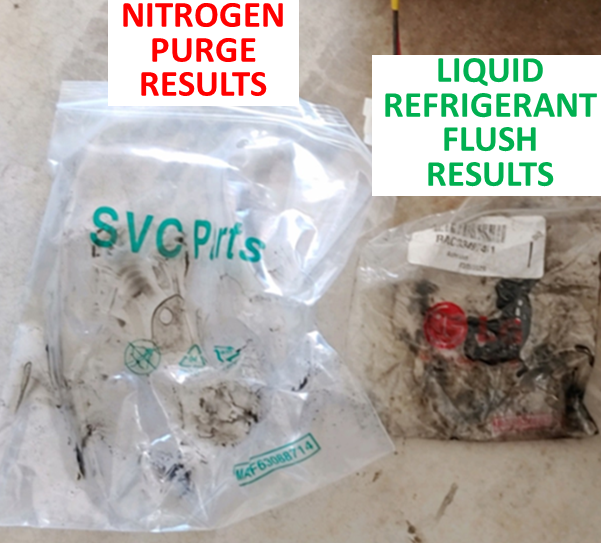

Nitrogen Purge – poor cleaning results. Nitrogen will push a restriction out and is necessary for pressure testing a system but will not pick up all debris.

The nitrogen is very dry and will pass through some debris and not pick them up. Then normal operations will cause restrictions.

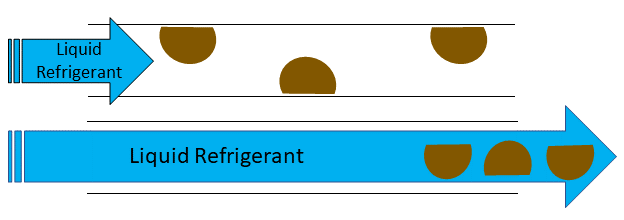

Flushing with liquid refrigerant, clears debris as it will “stick” to them and prevent future restrictions.

See the example below of the same unit flushed with only nitrogen first, then Liquid refrigerant.

This is why we need to use liquid refrigerant.

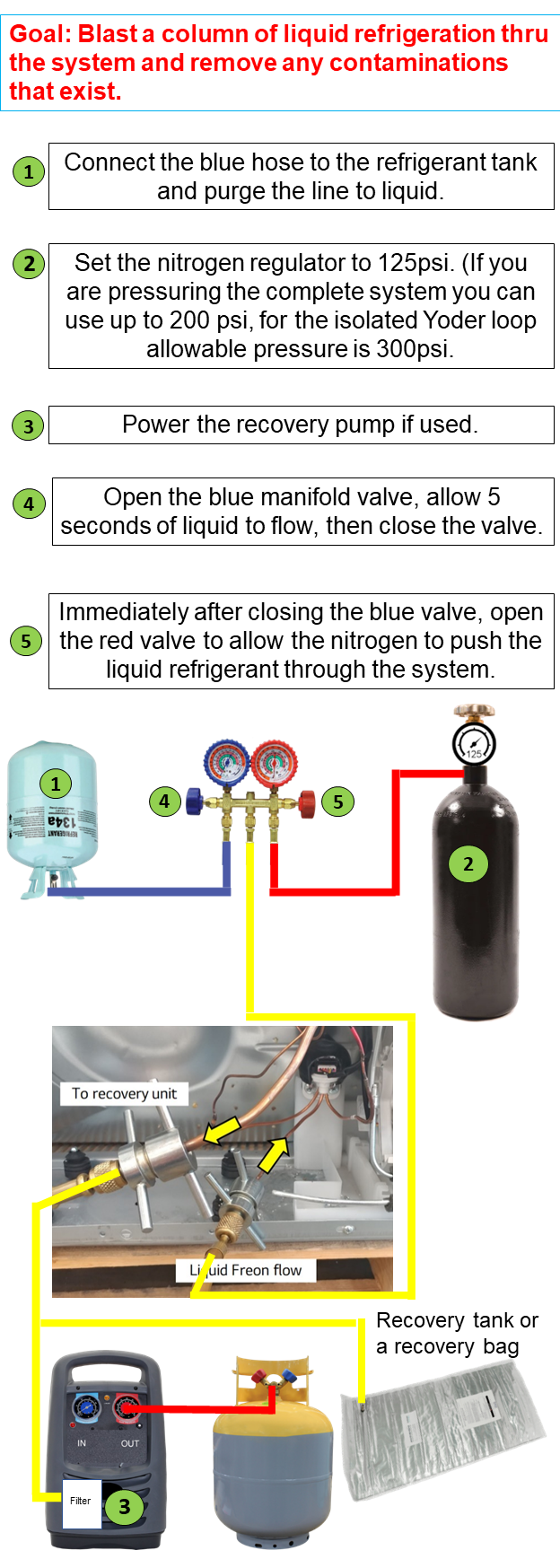

Flush Setup

How to Flush Dual Evaporator Units

Note that the 3-Way Valve will not operate under high pressure (above 100psi) of nitrogen. Set the 3-Way Valve to the fully open position BEFORE pushing nitrogen through the system. On the whole sealed system do not exceed 200 psi. On the isolated yoder loop do not exceed 300psi.

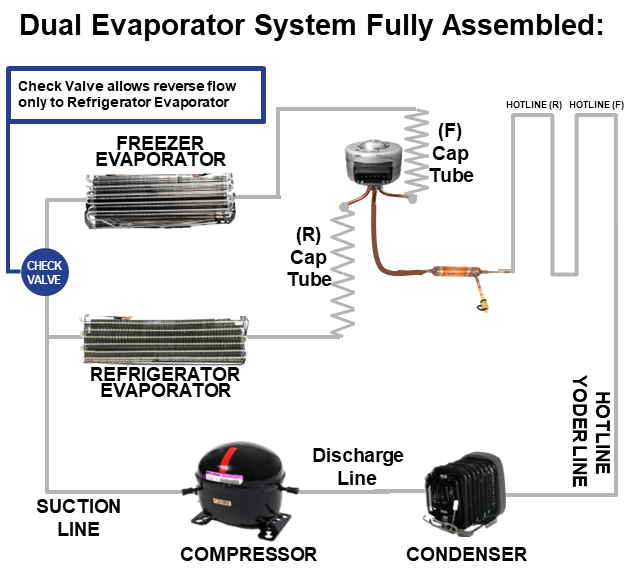

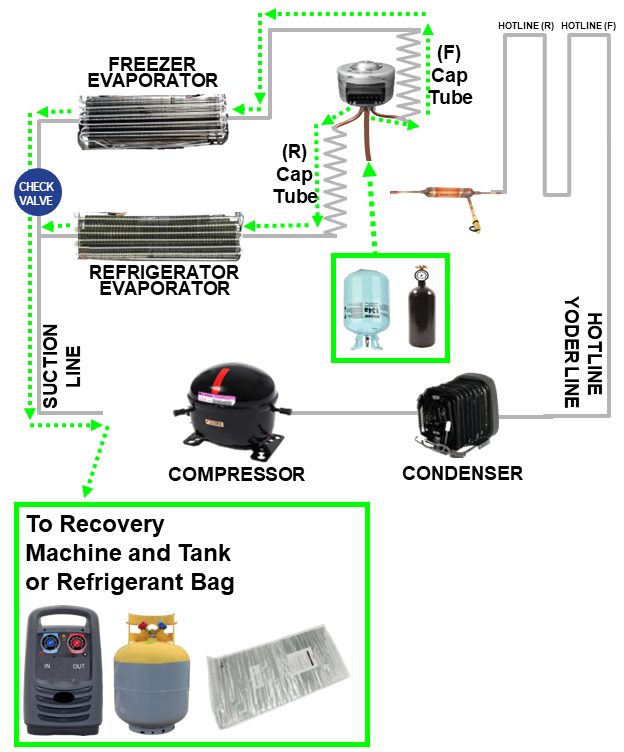

Reverse Flush Yoder Loop and Condenser

To reverse flush the high side of the system… Disconnect yoder loop from drier and discharge line from compressor. Push liquid refrigerant through the yoder loop to flush out any contamination in the internal line. Make sure and recover the refrigerant while flushing. If the system is heavily contaminated it is best to just replace the condenser coil instead of trying to flush it out. Flush the yoder until it is completely clean. See below illustration:

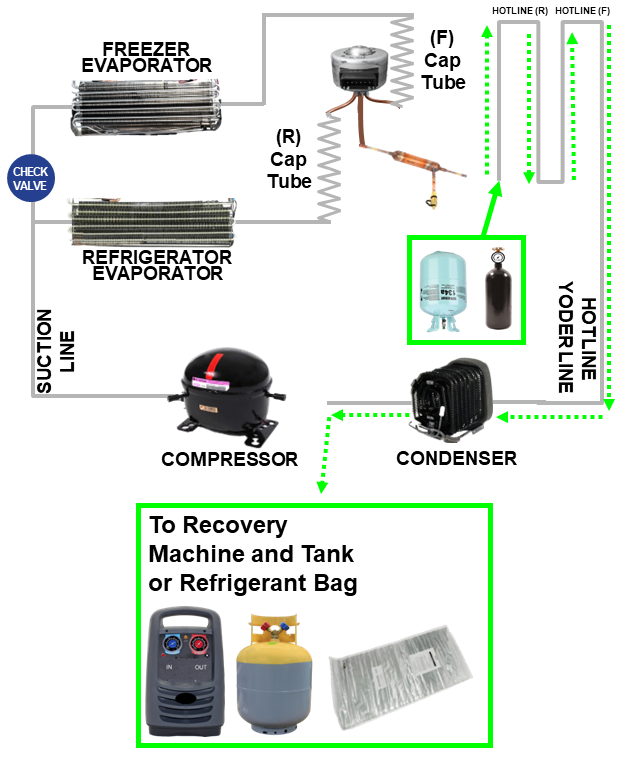

Forward Flush both Capillary Tubes and Evaporators:

To flush out both capillary tubes and evaporator coils… Disconnect the 3-way valve from the drier and the suction line from the Compressor. Push liquid refrigerant through the middle stem of the 3-way valve (make sure the 3-way valve is in the fully open position before flushing). Recover the refrigerant from the suction line while flushing. See below illustration:

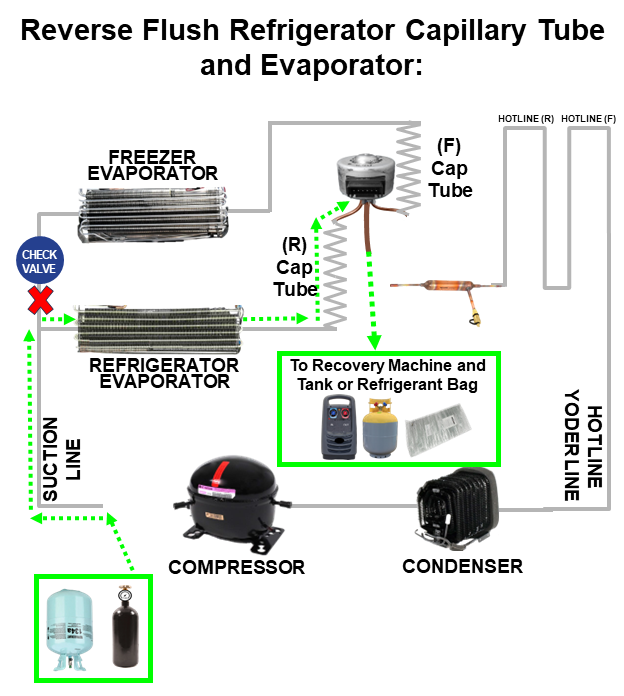

Reverse Flush Refrigerator Section Capillary Tube and Evaporator:

To reverse flush the refrigerator section capillary tube and evaporator…. Push liquid refrigerant through the suction line and recover from the middle stem of the 3-way valve. You cannot reverse flush the freezer evaporator or capillary tube from the suction line because there is a check valve inside the cabinet where the suction lines meet. See below illustration: